- Wire Rope Products

Wire Rope Products

- Lifting Slings

- Cargo & Ratchet straps

- Fittings

Fittings

- Fibre Rope

- Tools

- Assemblies

- Balustrade Wire

- BLOGS

- CONTACT

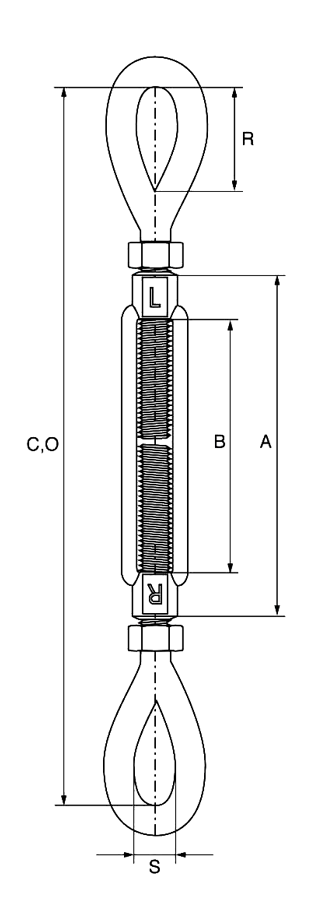

These Turnbuckle with Eye & Eye US Style are available in working load limits ranging from 0.54 tonne up to 34 tonne with sizes to suit. Ideal for applying consistent tension.

About Turnbuckle with Eye & Eye – US Style

These US style turnbuckles are made from drop forged, high tensile steel using SAE 1035 or SAE 1045 grade materials. The hot dipped galvanized finish coats the steel with zinc and provides excellent corrosion resistance. They can be used indoors and outdoors safely in temperatures ranging from -20°C up to +200°C.

The turnbuckle design uses a simple but effective mechanism featuring UNC (Unified National Coarse) threads. Both left-hand and right-hand threads are used, so when turned in one direction both screw rods move inward, thus shortening the length and increasing tension. By turning the turnbuckle in the opposite direction the length increases and so reduces the tension. This dual-threading design enables quick, precise adjustments.

These turnbuckles meet the performance requirements of ASTM F1145-92 (formerly US Fed. Spec. FF-T-791b. This ensures consistent quality and reliability for every turnbuckle. Every product goes through tough testing procedures. Proof loaded at 2 times the Working Load Limit (W.L.L.) and a minimum breaking load of 5 x W.L.L. for excellent safety margins.

All turnbuckles supplied by Rope Services Direct are clearly marked with CE and UKCA compliance marks, W.L.L., manufacturer's identification, size designation, traceability code, and L/R thread indication. Certification documents are available upon request for quality assurance and compliance verification.

Rope Services Direct has an excellent collection of tensioners including turnbuckles and rigging screws. They can be purchased in galvanized or stainless steel materials with a choice of termination options including jaws, hooks and eyes or a combination. We also have a large range of rope fittings which can be highly beneficial when working with ropes of the wire or fibre variety.

|

Product Code |

Size |

Take Up |

W.L.L. |

A |

B |

R |

S |

C |

O |

Weight |

|

|

inches |

inches |

t |

mm |

mm |

mm |

mm |

mm |

mm |

kgs |

|

TBEE6X4 |

¼ |

4 |

0.23 |

120 |

102 |

20 |

8.5 |

215 |

307 |

0.14 |

|

TBEE8X4.5 |

5/16 |

4 1/2 |

0.36 |

138 |

114 |

24 |

11.2 |

249 |

354 |

0.2 |

|

TBEE10X6 |

3/8 |

6 |

0.54 |

180 |

152 |

28.5 |

13.5 |

308 |

460 |

0.34 |

|

TBEE12X6 |

½ |

6 |

1 |

190 |

152 |

36.5 |

18 |

380 |

532 |

0.71 |

|

TBEE12X9 |

½ |

9 |

1 |

267 |

229 |

36.5 |

18 |

456 |

685 |

0.85 |

|

TBEE12X12 |

½ |

12 |

1 |

343 |

305 |

36.5 |

18 |

510 |

815 |

1 |

|

TBEE12X18 |

½ |

18 |

1 |

495 |

457 |

36.5 |

18 |

684 |

1081 |

1.6 |

|

TBEE16X6 |

5/8 |

6 |

1.59 |

203 |

152 |

45 |

22.5 |

398 |

550 |

1.17 |

|

TBEE16X9 |

5/8 |

9 |

1.59 |

279 |

229 |

45 |

22.5 |

474 |

703 |

1.42 |

|

TBEE16X12 |

5/8 |

12 |

1.59 |

355 |

305 |

45 |

22.5 |

550 |

855 |

1.67 |

|

TBEE19X6 |

¾ |

6 |

2.36 |

213 |

152 |

53 |

25.4 |

448 |

600 |

1.87 |

|

TBEE19X9 |

¾ |

9 |

2.36 |

289 |

229 |

53 |

25.4 |

524 |

753 |

2.22 |

|

TBEE19X12 |

¾ |

12 |

2.36 |

365 |

305 |

53 |

25.4 |

600 |

900 |

2.57 |

|

TBEE19X18 |

¾ |

18 |

2.36 |

517 |

457 |

53 |

25.4 |

752 |

1209 |

3.27 |

|

TBEE22X12 |

7/8 |

12 |

3.27 |

374 |

304 |

60 |

32 |

630 |

934 |

3.77 |

|

TBEE22X18 |

7/8 |

18 |

3.27 |

527 |

457 |

60 |

32 |

782 |

1239 |

4.7 |

|

TBEE25X6 |

1 |

6 |

4.54 |

233 |

152 |

76 |

37 |

552 |

704 |

4.1 |

|

TBEE25X12 |

1 |

12 |

4.54 |

385 |

305 |

76 |

37 |

704 |

1009 |

5.33 |

|

TBEE25X18 |

1 |

18 |

4.54 |

537 |

457 |

76 |

37 |

856 |

1313 |

6.56 |

|

TBEE25X24 |

1 |

24 |

4.54 |

690 |

610 |

76 |

37 |

1010 |

1620 |

7.83 |

|

TBEE32X12 |

1.25 |

12 |

6.89 |

388 |

305 |

90 |

46 |

776 |

1081 |

9.1 |

|

TBEE32X18 |

1.25 |

18 |

6.89 |

541 |

457 |

90 |

46 |

928 |

1385 |

10.94 |

|

TBEE32X24 |

1.25 |

24 |

6.89 |

693 |

610 |

90 |

46 |

1080 |

1690 |

12.75 |

|

TBEE38X12 |

1.5 |

12 |

9.71 |

403 |

305 |

103 |

53.8 |

838 |

1143 |

12.93 |

|

TBEE38X18 |

1.5 |

18 |

9.71 |

555 |

457 |

103 |

53.8 |

990 |

1447 |

15.43 |

|

TBEE38X24 |

1.5 |

24 |

9.71 |

708 |

610 |

103 |

53.8 |

1144 |

1754 |

17.97 |

|

TBEE44X18 |

1.75 |

18 |

12.7 |

571 |

457 |

117 |

60.5 |

1076 |

1544 |

23.37 |

|

TBEE44X24 |

1.75 |

24 |

12.7 |

724 |

610 |

117 |

60.5 |

1230 |

1840 |

26.91 |

|

TBEE50X24 |

2 |

24 |

16.8 |

740 |

610 |

146 |

68 |

1400 |

2010 |

39.93 |

|

TBEE63X24 |

2.5 |

24 |

27.2 |

795 |

610 |

165 |

79 |

1490 |

2100 |

70.96 |

|

TBEE70X24 |

2.75 |

24 |

34 |

795 |

610 |

178 |

82.5 |

1562 |

2172 |

82.22 |